The Un1co product family was born from a consideration about the state of the art of the installer’s work in the field. Operators are often in the condition to transport a lot of material, expensive and delicate, losing efficiency; or to operate at great heights on overhead cabling with a high risk of accidental fall of the instrumentation, rather than having to intervene, especially in delivery operations, bringing with it bulky and not very functional bags or boxes.

The solution had to be found in a modular system, easy to transport, capable of containing everything needed to operate independently or secure it firmly to avoid falls.

Fibernet, once studied the real needs of the installers has started the design of a series of products to respond to all these requests.

UN1CO ONE

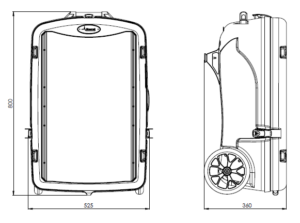

Un1co One is a suitcase designed and developed by Fibernet for the handling and transport of primary instrumentation for processing of optical fibers on the field, which can be transformed into a stable and multi-equipped workbench through a special system.

Inside, different compartments capable of containing – and protecting – not only the delicate optical instruments used on the field, but also the equipment and consumables used in the processing.

Fibernet’s engineers therefore began to develop proposals and hypotheses for the realization of this system, starting the process from scratch, just because such a product did not exist on the market. The first prototype that Fibernet made was developed on an aluminum chassis: a square armature, with locked drawers and spaces, which however did not make the product suitable because of the weights and dimensions and due to the lack of modularity.

A second version of the product was developed, reengineered, designed and built to scale with a 3d printer, which best responded to the initial requests. This version was made entirely of carbon, to contain the weights and ensure maximum resistance on the field. And it is precisely this version of the product that was presented, enjoying wide public success, during the ECOC 2018 in Rome.

The feedback obtained in this event allowed the development of the definitive product. Weights even more contained, simpler interiors to manage in order to better contain the most widespread instrumentation on the market, greater simplicity in the “work table” version: these measures have allowed Un1co one to obtain broad consensus also on the San Diego OFC in 2019.

The external body of Un1co is established by two ABS half-shells which, together with an internal structure in expanded polypropylene (PPE)

The external body of Un1co is established by two ABS half-shells which, together with an internal structure in expanded polypropylene (PPE)  the unit provides maximum rigidity and lightness to the suitcase.

the unit provides maximum rigidity and lightness to the suitcase.

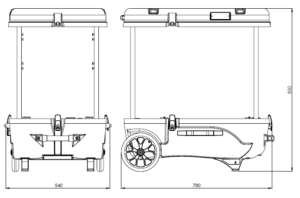

Once open, Un1co offers a selected worktop and height about 85 cm from the ground, ideal for standing work, while the lower part of the suitcase remains raised about 7 cm from the ground. The scratch-resistant work surface is made of ABS (2 mm thick).

The key components of the worktop are the two multifunction bars mounted on the front part of the lid, suitable for anchoring the flasks, using the special brackets with hammer screws that guarantee the immediate installation of any type of accessory. equipped with additional shelves, made of painted aluminum, which can be easily mounted to extend the work surface up to 1285 mm.

All the interiors are arranged in three separate and distinct areas for housing various tools and utensils essential for field operations. These areas are delimited and protected during transport by PPE walls and covered by painted aluminum doors

Visit the website